Air Cooled Condenser Fans/ACC Fans

ACC condenses steam in the finned tube by the airflow of air-cooled condenser fans. At Maya, we offer an energy-efficient FRP air-cooled condenser fan which is up to 40% power saving compared to conventional fans.

Our efficiency claims are validated through rigorous testing procedures that comply with ASME PTC 30.1 standards for Air-Cooled Steam Condensers, ensuring reliable and consistent performance measurements.

This significant power reduction translates to substantial operational cost savings while maintaining optimal cooling performance. Our advanced FRP construction and aerodynamic design principles, combined with industry-standard testing methodologies, deliver measurable energy efficiency improvements that directly impact your bottom line.

For decades, Maya Fan has been a leading manufacturer following ASME standards for varying industry needs. We provide special low noise fan series with advanced acoustic design, reducing noise up to 10 dB less than conventional ACC fans.

You get the unsurpassed integrity, performance, and reliability at a price that may surprise you.

FAN DIAMETER IN FOOT

Up to 40% power saving

AIR FLOW UP TO (CMS)

STATIC PRESSURE IN MM OF WG

NUMBER OF BLADES UP TO

MAYA AIR COOLED CONDENSER FAN STRENGHT

CREATIVE IDEAS

AT Maya Fans we always remain creative to deal with the challenges in the field of tailor-made ACC fans. So far we have developed fans for up to 1200 mm chord width for low RPM and low sound fans.

EXCELLENT FEATURES

We are a pioneer to introduce the most efficient aerodynamic hub. It is our registered drawing, we also introduce many more features in design as well as in manufacturing.

FULLY RESPONSIVE

AT Maya Fan We never force-fit our standard existing fans. But remain responsive to input design data and develop new products as and when required.

AIR-COOLED CONDENSER FAN DEVELOPMENT PROCESS

Every OEM uses a different design of condenser. So they require a customized fan. And we do not Force customers to compromise with the standard available product. But remain open to new development. and the following are the step for customized ACC fan developments-

FAN DATA COLLECTION

Accurate data (Fan duty point) is essential for fan development. We collect field data using technical expertise and high-tech equipment following ASME PTC 11 standards.

FAN DESIGN

We analyze collected data and conclude for a specific design point. As well as keep a range of operations in mind while developing a new fan.

VALIDATION

It is a must to confirm each of the design outcomes. It helps to decide on the best solution, and we have full modeling and testing facilities in the house.

PRODUCTION

Once the final fan design concluded, it was handed over to the production team. They prepare the tool for production.

Air Cooled Condenser Fans Key Feature

High Efficient FRP fan impeller.

Low Operating Costs.

Up to 40% power saving against conventional fans.

Long Life fan Construction.

Good Performance in all weather conduction.

Zero Downtime with minimum care.

Fast emergency response.

Very low payback period in case of replacement of existing fan.

Hollow blade construction Reduce fan weight and increase life of mechanical components.

Zero Cost Solution for power saving opportunity.

Why choose Maya ACC fan?

Low Operating Costs

- Maya high-efficient airfoil blade design following ASHRAE efficiency principles

- Optimization of twist cord and cross-section provide high efficiency.

- The involvement of the most advanced composite material. Reduces turbulence and produces smooth linear airflow.

- Best design for the duty point No oversizing of the fan.

Long Life Construction

- Most of the parts are made of Heavy-duty composite and hot-dip galvanized material. It meets the corrosion resistance and equipment life requirements of heavy industrial applications. While still delivering an outstanding value.

- A lightweight impeller, thus, increases the life of all the mechanical components.

- Air Cooler Fans are also available with Series 300 stainless steel. It is an optional upgrade that comes with a 5-year limited warranty.

- Maya ACC Fans are manufactured in ISO-2015-certified facilities. It attests to our commitment to comprehensive quality processes and systems.

Fast emergency response.

- Ready-made fan available.

- The minimum stock of the fan spare is maintained.

- Low manufacturing time because of zero outsourcing.

- An expert team is available for fan installation.

Quiet by Design

- The composite blade has a glossy surface finish that offers smooth airflow.

- low tip speed design (Noise is directly proportioned to tip speed).

- No outsourcing of full quality control thus achieves the least tip clearance.

- Special design available for extra low noise fan which can reduce noise up to 10 dba compares to conventional fans.

Performance for All Seasons

The fan is a constant flow machine. To maintain its performance, despite critical variation in weather our fans are designed for a broad range of operations. Our fans are having a good amount of reserve margin for both airflow and static pressure. Thus fan performs throughout the year in all type of seasons.

Low Maintenance/Less Downtime

- Maya FRP condenser fans are made of high-quality material and robust design.

- Maya design fan for low operating tip speed, it increases system life and also reduces the chance of failure.

- Unlike the painted fan, we do provide a permanent coating of a gel coat that remains an integral part of the fan blade body. And it does not get separated due to erosion.

Maya FRP condenser fan construction

Here is the list of Maya condenser fan component with a there brief detailing

Fan Blade

Maya condenser fan blade made of latest airfoil similar to an airplane wing. We do select the most advanced airfoil possible for the fan to provide maximum efficiency. Due to this, we achieved superior performance. Our blade is robust in construction and designed for 7-10 times of operating load. We also provide superior wear resistance material to maintain surface stability for a long period of time. This prevents efficiency deterioration over a period of time.

This FRP condenser fan blade is having some very charismatic properties. It is very much possible to produce any complicated shape with ease. Thus providing an economical solution.

some of its special features are listed below –

- High strength at low weight.

- Good impact, fatigue, and Tensile Strength (Ultimate)

- Excellent environmental resistance.

- Excellent chemical and corrosion resistance.

- Superior surface finish.

- Better life of the entire condenser fan system due to low assembly weight.

- Low moment of inertia help for the selection of optimum motor and reduce over-design due to higher starting torque thus motor operate under a better range of efficiency.

Fan Hub / Boss

Hub used in condenser fans is heavy in construction. In this, we are using a heavy thickness mild steel plate, cast iron or Aluminum clamp, and stainless steel hardware. It provides long life, as we coat all mild-steel parts with heavy thickness of zinc. Note – Optionally we also customize hub/Boss on demand of the customer, like caste hub boss, Spider Type Fabricated hub, etc.

Key Feature

- Heavy-duty MS fabricated.

- Hub is dynamically balanced as per ISO 1940 grade 6.3 or 2.5 if required.

- The individual part of the hub is moment balanced.

- All the MS parts are hot-dip galvanized Option for different grades of ss plate is also available.

- Nut bolts used are of coated HT or stainless steel series.

- For sea weather applications Solvent Free, Self-levelling Coatings are available.

Taper Locking

In most of our condenser fans, we preferred to have a taper locking arrangement. It is a proven part of the easy assembly in the field. These taper lockings are made of Cast iron or stainless steel.

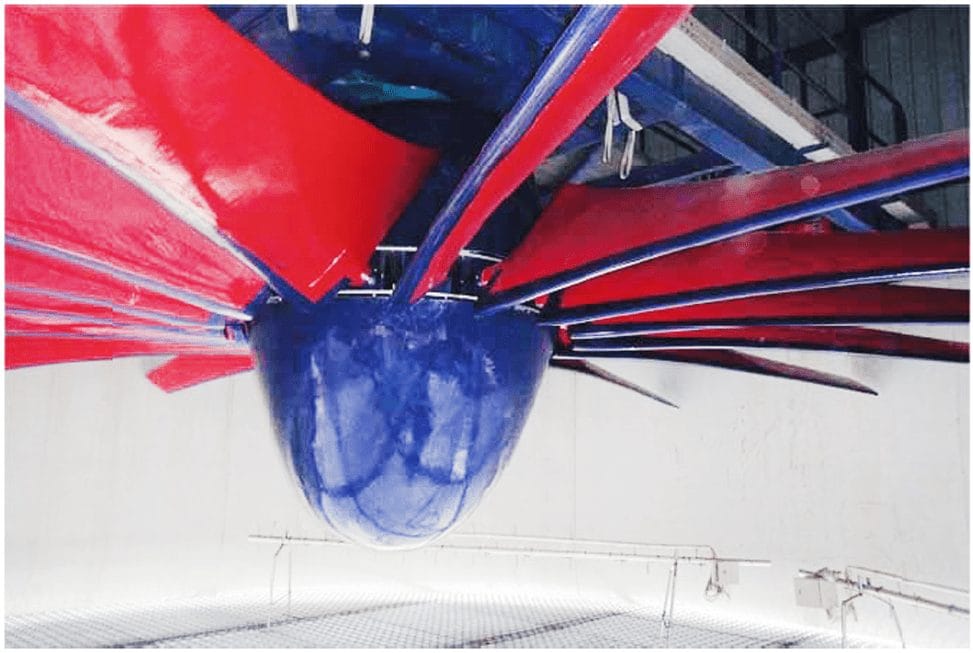

AERODYNAMIC HUB

is made of E-glass anti-static fiber, having UV protection, it is available in the segment for ease of transportation.

- This hub maintains laminar airflow at the center of the fan and avoids eddies generation.

- It has a high surface finish for smooth airflow.

- Anti-static properties to avoid the static charge.

- Seals the fan circuit and avoids air recirculation.

- With the use of an aerodynamic hub, The designer gets the freedom to reduce the mechanical hub dimension.

Unlock All Feature Of Maya Fan With Our Special Feature Presentation

FEW OF OUR PRESTIGIOUS CONDENSER FANS CUSTOMER

❓ Frequently Asked Questions – Air Cooled Condenser Fans/ACC Fans

What are the advantages of FRP over aluminum fans?

FRP fans offer better corrosion resistance, lower weight, reduced noise, and longer lifespan compared to aluminum fans.

How much energy can I save by using FRP cooling tower fans?

You can save up to 40% power over metallic fans and up to 25% over conventional FRP fans.

Are these fans suitable for coastal or chemical environments?

Yes, FRP construction makes them highly suitable for humid, saline, or chemically aggressive locations.

What is the expected lifespan of an FRP cooling tower fan?

Typically 15–25 years depending on operational conditions and maintenance.

What is an air cooled condenser fan?

Explain its role in an ACC system, typical applications (power plants, refineries), and how it differs from other industrial fans.

How does an ACC fan work?

Briefly explain the working principle — how it helps remove heat from steam by forcing air over condenser tubes.

Where are ACC fans used?

Target keywords like power plants, thermal power plants, petrochemical plants, refineries, industrial cooling.

What are the benefits of using efficient ACC fans?

Discuss energy efficiency, low maintenance, reduced noise, higher heat transfer efficiency.

How to select the right air cooled condenser fan?

Mention key selection factors: airflow, fan diameter, speed, blade material, noise levels, ambient conditions.

What types of blades are used in ACC fans?

Cover materials — FRP (Glass Fiber Reinforced Plastic), aluminium, steel — and why FRP is preferred.

How do ACC fans improve plant performance?

Explain how better cooling improves turbine efficiency, reduces fuel consumption.

What is the typical lifespan of an ACC fan?

Talk about durability, design life, and factors affecting it — like corrosion resistance.

How do you maintain an air cooled condenser fan?

Basic checks: vibration, balancing, cleaning blades, checking for corrosion.

Does Maya Fan Air Engineering offer custom ACC fan solutions?

Emphasize your ability to design custom fans to match specific site conditions.

How energy efficient are Maya Fans’ ACC fans?

If you have efficiency data, highlight it here — this signals your value to Google and buyers alike.

Do ACC fans make noise?

Explain typical noise levels, noise control features, and how your designs address this.

Can ACC fans be retrofitted to existing systems?

Good for targeting retrofit/upgrade keywords. Explain feasibility.

What makes Maya Fan Air Engineering ACC fans different from others?

Highlight your USPs: superior design, performance, after-sales service, local manufacturing.

How can I get a quote for an air cooled condenser fan?

Link to your contact page, encourage RFQs.