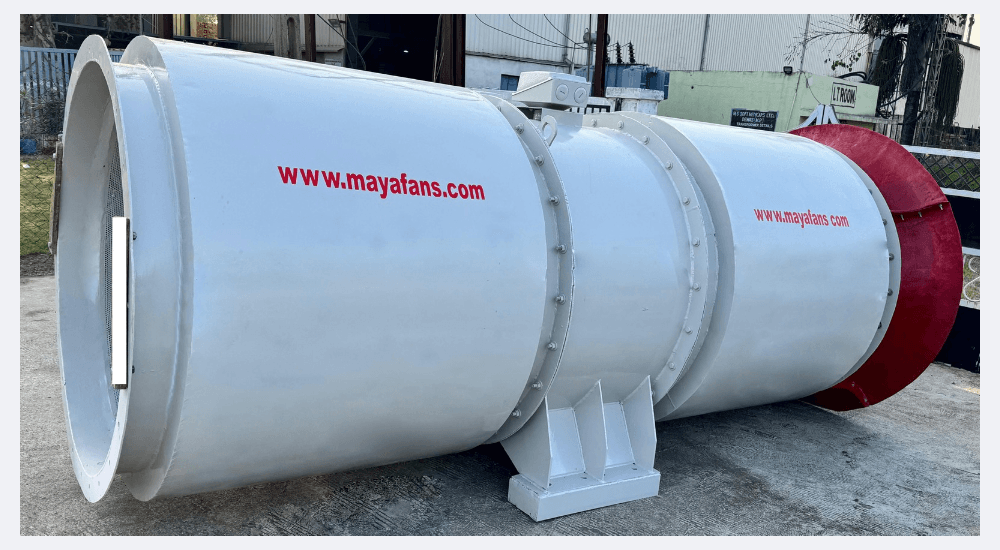

In the demanding world of underground mining, efficient and reliable ventilation systems are critical for worker safety and operational productivity. At Maya Fan Air Engineering Pvt Ltd, we’re pushing the boundaries of innovation with our cutting-edge carbon fiber mining ventilation fans. These state-of-the-art fans deliver unmatched performance, energy savings, and durability, transforming how mines manage airflow. In this blog, we’ll explore the technical advantages of carbon fiber in mining fans, why Maya Fans leads the industry, and how our solutions are redefining mine ventilation.

Why Mine Ventilation Matters

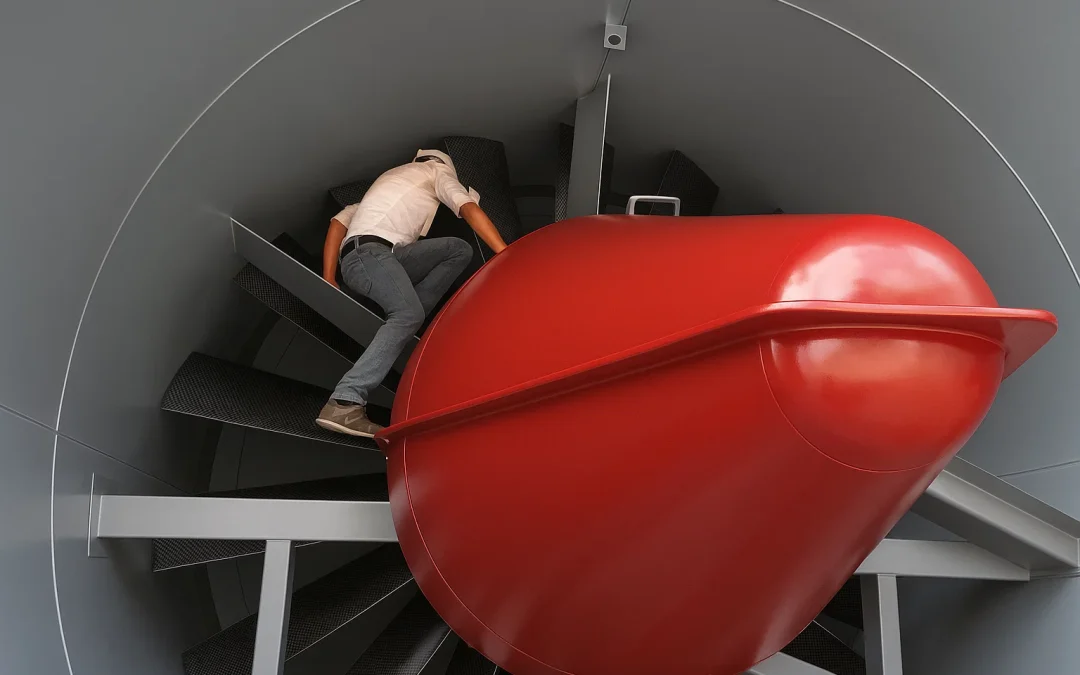

Underground mines are challenging environments where oxygen supply, hazardous gas dilution, and temperature regulation are non-negotiable. Ventilation fans serve as the lifeline of these operations, ensuring fresh air reaches workers while exhausting harmful gases and heat. Traditional fans made from steel or aluminum often struggle to balance efficiency, durability, and cost. That’s where carbon fiber steps in as a game-changer.

Our mining ventilation fans are engineered to overcome these challenges, offering superior performance tailored to the unique needs of coal, gold, uranium, and other mining operations. Let’s dive into the technical aspects that make carbon fiber the material of choice for modern mine ventilation.

The Technical Edge of Carbon Fiber in Mining Fans

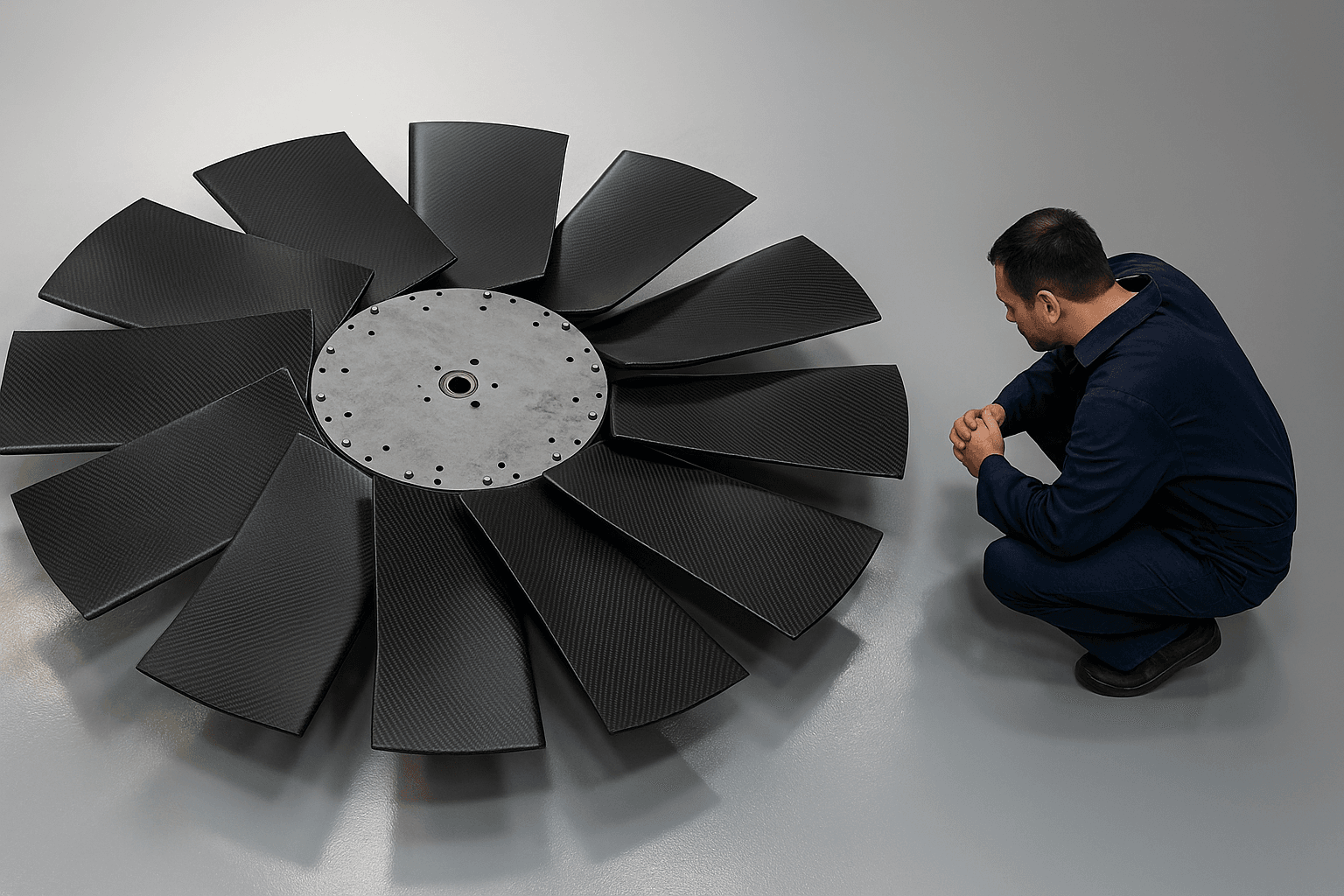

Carbon fiber, a lightweight yet incredibly strong composite material, is revolutionizing industries from aerospace to automotive—and now mining. Here’s why it’s the perfect fit for ventilation fans:

Unmatched Strength-to-Weight Ratio

Carbon fiber is significantly lighter than steel or aluminum while being several times stronger. This allows us to design fan blades that are:

- Robust: Capable of withstanding high tip speeds (up to 22,000 FPM) and harsh underground conditions.

- Lightweight: Reducing mechanical stress on bearings and motors, extending equipment lifespan.

The result? Fans that operate smoothly under extreme loads, minimizing downtime and maintenance costs.

Superior Energy Efficiency

Energy consumption is a major concern in mining, where ventilation systems can account for up to 50% of total energy costs. Carbon fiber’s aerodynamic properties enable us to craft blades with advanced airfoil designs, similar to those used in aircraft wings. These blades:

- Maximize airflow with minimal power input.

- Achieve up to 35% energy savings compared to traditional metal fans.

For mine operators, this translates to lower operational costs and a reduced carbon footprint, aligning with global sustainability goals.

Corrosion and Wear Resistance

Underground mines are corrosive environments with high humidity, dust, and chemical exposure. Unlike steel, which rusts, or aluminum, which can degrade, carbon fiber is inherently corrosion-resistant. At Maya Fans, we enhance this with:

- Anti-static coatings for safe use in coal mines where explosive gases are a risk.

- UV-protective layers to maintain surface integrity over time.

Our carbon fiber blades maintain their efficiency and structural integrity for years, even in the toughest conditions.

Customizable and Precise Design

Carbon fiber’s flexibility allows for complex shapes that optimize aerodynamic performance. Using advanced computational fluid dynamics (CFD) and in-house testing, we tailor each fan to specific mine requirements, including:

- Airflow volume

- Static pressure

- Operating temperature

- Diameter constraints

This bespoke approach ensures our fans deliver peak performance without oversizing, a common issue with off-the-shelf solutions.

Low Noise Operation

Noise pollution is a concern in mining operations. Our carbon fiber fans are designed to reduce turbulence and vibration, resulting in noise levels up to 10 dBA lower than conventional fans. This creates a safer and more comfortable working environment for miners.

Why Choose Maya Fans’ Carbon Fiber Mining Ventilation Fans?

At Maya Fan Air Engineering, we don’t just manufacture fans—we engineer solutions that drive efficiency, safety, and reliability. Here’s what sets us apart:

- Proven Expertise: With over 600 installations across India’s largest mines, including SECL, ECL, and HZL, we’re the trusted choice for critical ventilation needs.

- Tailor-Made Solutions: We never force-fit standard fans. Our team collects precise field data using high-tech equipment to design fans that match your mine’s unique conditions.

- Innovative Materials: Our carbon fiber fans use advanced epoxy composites, offering anti-static properties and durability unmatched by steel or aluminum.

- Comprehensive Support: From installation and performance testing to maintenance and upgrades, we provide end-to-end services to keep your ventilation system running smoothly.

Discover our full range of carbon fiber mining ventilation fans to see how we’re redefining mine ventilation with cutting-edge technology.

Real-World Impact: Case Studies

Our carbon fiber mining fans have delivered transformative results for clients across the globe. Here are two examples:

- Coal Mine in Central India: A major coal mine replaced its steel auxiliary fans with Maya’s carbon fiber fans, achieving a 30% reduction in energy consumption and a 50% increase in blade lifespan.

- Uranium Mine in South India: Facing high corrosion issues, a uranium mine switched to our anti-static carbon fiber booster fans, eliminating maintenance downtime and improving airflow by 25%.

These success stories highlight how our fans enhance safety, cut costs, and boost productivity in real-world mining operations.

The Future of Mine Ventilation

As the mining industry faces rising energy costs and stricter environmental regulations, innovative solutions like carbon fiber ventilation fans are paving the way for a sustainable future. By combining advanced materials, precision engineering, and a customer-centric approach, Maya Fans is leading the charge in transforming mine ventilation systems.

Whether you’re operating a coal, manganese, or gold mine, our carbon fiber fans offer a reliable, cost-effective, and eco-friendly solution to your ventilation challenges. Ready to upgrade your mine’s airflow system? Contact us today to discuss your requirements and discover how we can help.

Conclusion

Carbon fiber mining ventilation fans represent the future of safe, efficient, and sustainable mining. With their lightweight design, energy-saving performance, and unmatched durability, they’re the ideal choice for modern mines. At Maya Fan Air Engineering, we’re proud to lead this revolution, delivering tailor-made solutions that empower mines to thrive.

Visit www.mayafans.com to learn more about our innovative fans and how they can transform your operations. Let’s breathe new life into your mine ventilation system!

Keywords: carbon fiber mining fans, mine ventilation fans, mining ventilation systems, energy-efficient fans, anti-static fans, Maya Fans, underground mining ventilation, durable mining fans, low-noise ventilation fans

Meta Description: Discover how Maya Fans’ carbon fiber mining ventilation fans revolutionize underground mining with up to 35% energy savings, corrosion resistance, and tailored designs. Learn more at www.mayafans.com.

Recent Comments